PART II

In our previous article, we presented our design process, as well as the equally important stage of selecting fabrics and accessories for our new collection Autumn/Winter 2016. Once these stages have been completed, it is time to start the actual manufacturing process. Now, we order all the necessary knits and fabrics with our reliable suppliers. Once they have been delivered to us, we can start to prepare the patterns. Some of them go to the printing or embroidery department, depending on a specific design project. After applying all decorations, we move on to the sewing stage. During this phase, we rely on the utmost precision of our staff. While manufacturing our products, we focus on quality, not quantity. After the sewing process, all items are carefully verified, and all the products which fail to meet our standards are improved or rejected. The final step is to prepare the finished products for sale – the ironing and packing process.

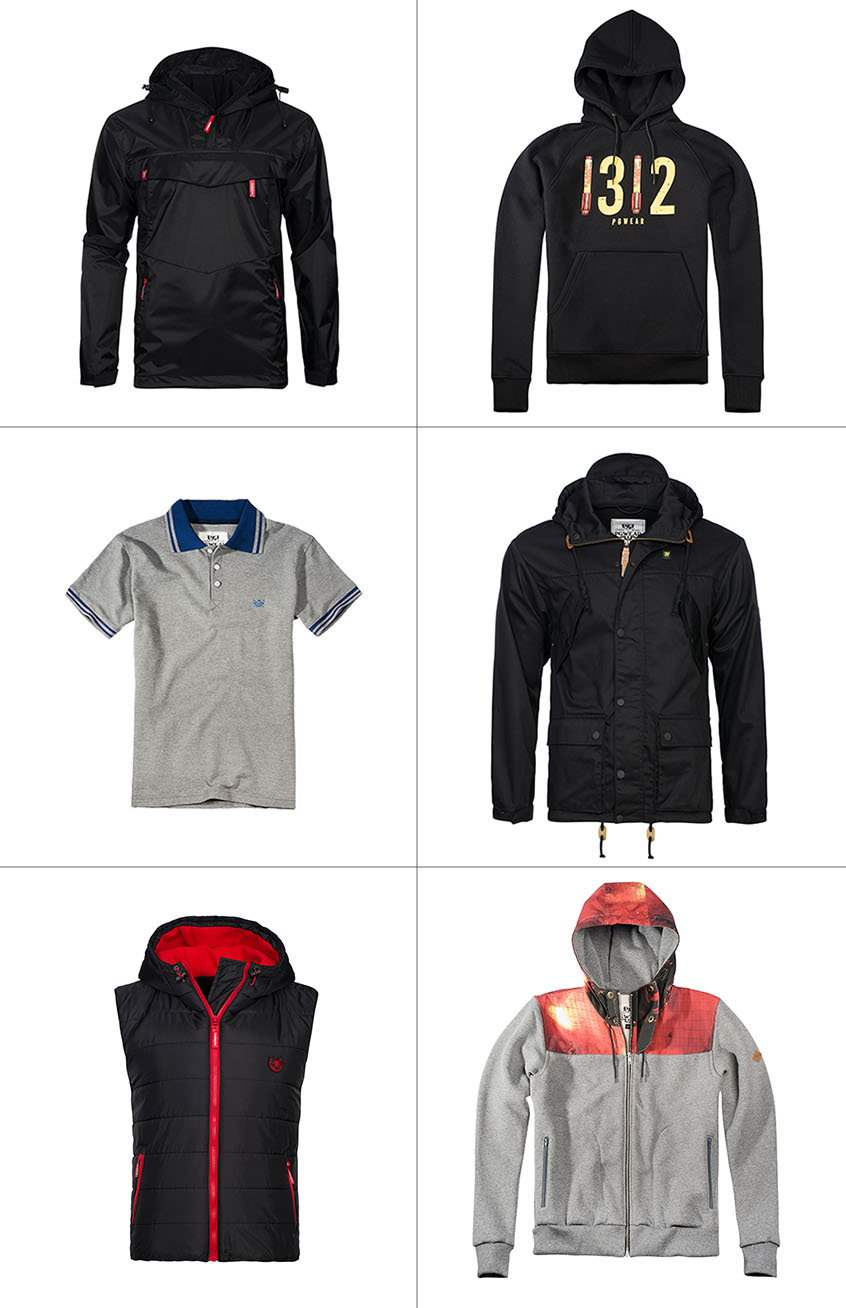

The collection PGWEAR Autumn/Winter 2016 features 70 different products designed and manufactured from scratch, making the production process quite long. The time necessary to perform your orders is much shorter.

Should you have any questions, feel free to contact us at: customs@pgwear.net.

Top quality fan apparel

Contact us